Розшифровка відмінностей - гідромуфти типу T, TV та TVV у промисловому застосуванні

2025-11-04 15:01Decoding the Differences - T-Type, TV-Type, and TVV-Type Fluid Couplings in Industrial Applications

FOR IMMEDIATE RELEASE

In the field of industrial power transmission, Fluid Coupling technology continues to play a vital role in enhancing operational efficiency and equipment protection. The evolution from standard T-type to advanced TV-type and TVV-type Hydrodynamic Couplings represents significant technological progress in torque transmission and motor protection systems. This comprehensive analysis examines the distinct characteristics, operational advantages, and optimal application scenarios for each Fluid Coupling variant.

Technical Evolution and Structural Innovation

The development of Hydrodynamic Coupling technology has followed a clear path of innovation, with each generation addressing specific industrial challenges through structural enhancements:

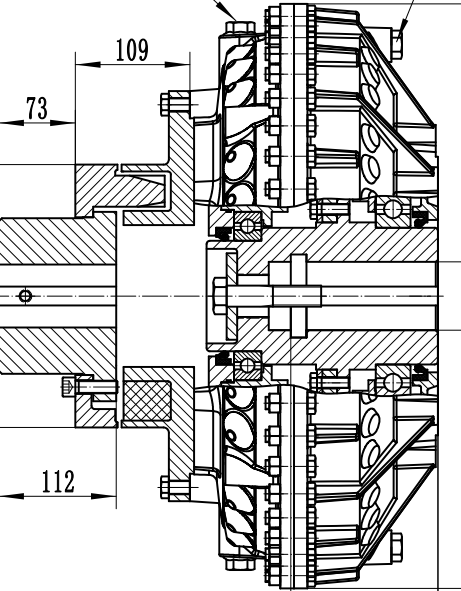

T-Type Fluid Coupling: The Foundation of Torque Limiting

As the standard limited-slip Fluid Coupling, the T-type represents the fundamental design in Hydrodynamic Coupling technology. This basic configuration features a single working chamber without additional auxiliary compartments, providing essential torque transmission and motor protection functions.

Core Structural Characteristics:

- Single working chamber design

- Fixed fluid volume operation

- No auxiliary chamber integration

- Straightforward mechanical construction

Primary Advantages:

- Simplified Motor Protection: Enables smooth motor start-up by providing no-load starting conditions

- Basic Overload Security: Automatically disengages during equipment jamming or excessive loading situations

- Economic Efficiency: Lower initial investment and maintenance requirements

- Reliable Performance: Proven operational reliability in standard applications

Industrial Applications:

This Hydrodynamic Coupling excels in fixed-speed equipment requiring fundamental protection, particularly in conveyor systems, basic material handling equipment, and standard industrial drives where speed regulation is unnecessary.

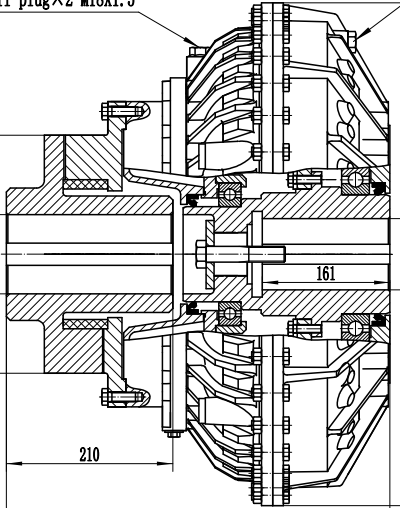

TV-Type Fluid Coupling: Enhanced Performance with Auxiliary Chamber

The TV-type Fluid Coupling introduces significant design improvement through the incorporation of a rear auxiliary chamber. This structural enhancement enables more sophisticated torque management and startup characteristics, representing a substantial advancement in Hydrodynamic Coupling technology.

Advanced Structural Features:

- Primary working chamber combined with rear auxiliary chamber

- Dynamic fluid exchange capability

- Enhanced torque regulation mechanism

- Improved thermal management

Operational Benefits:

- Superior Startup Control: Provides gradual torque buildup during acceleration phases

- Advanced Load Distribution: Effectively manages peak torque demands

- Extended Equipment Longevity: Reduces mechanical stress on connected components

- Adaptive Performance: Accommodates varying operational conditions

Application Scope:

This Hydrodynamic Coupling configuration proves particularly valuable in applications demanding controlled acceleration, including crusher systems, heavy-duty conveyors, and equipment with high inertial loads.

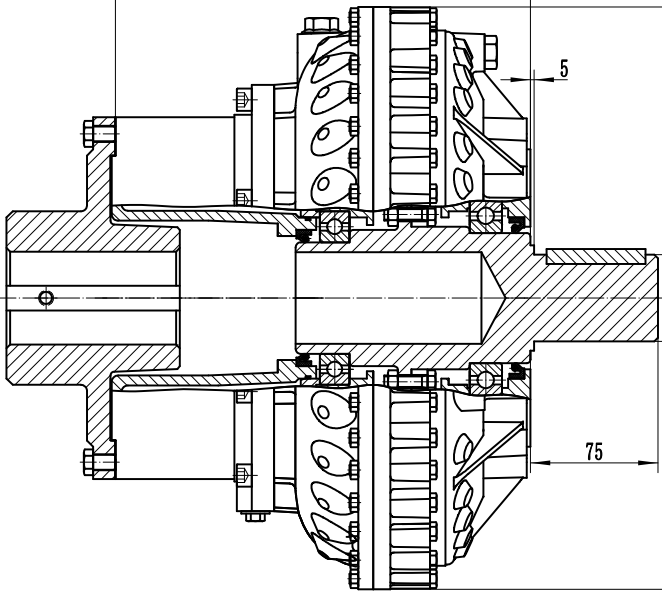

TVV-Type Fluid Coupling: Optimized Performance with Extended Auxiliary Chamber

The TVV-type Fluid Coupling represents the pinnacle of conventional Hydrodynamic Coupling design, featuring an extended rear auxiliary chamber that delivers superior torque management and operational control. This advanced Fluid Coupling configuration addresses the most demanding industrial applications.

Premium Structural Attributes:

- Elongated rear auxiliary chamber design

- Optimized fluid circulation path

- Enhanced heat dissipation capability

- Precision-engineered flow dynamics

Performance Advantages:

- Exceptional Torque Control: Delivers precise torque management throughout operational range

- Optimal Thermal Performance: Maintains stable operating temperatures under heavy loads

- Maximum Protection: Provides comprehensive system protection against overload conditions

- Energy Efficiency: Minimizes power losses during operation

Implementation Areas:

This premium Hydrodynamic Coupling solution serves critical applications in mining operations, heavy processing equipment, and high-value machinery where maximum protection and performance are essential requirements.

Comparative Technical Analysis

Startup Performance:

- T-Type Fluid Coupling: Basic startup characteristics with fundamental torque limitation

- TV-Type Hydrodynamic Coupling: Improved startup control through auxiliary chamber function

- TVV-Type Fluid Coupling: Optimized startup performance with extended chamber benefits

Torque Management Capability:

- T-Type Hydrodynamic Coupling: Standard torque limitation suitable for basic applications

- TV-Type Fluid Coupling: Enhanced torque control for moderate demanding conditions

- TVV-Type Hydrodynamic Coupling: Superior torque management for critical applicat

ions

Application Suitability:

- T-Type Fluid Coupling: Standard industrial applications with consistent operational demands

- TV-Type Hydrodynamic Coupling: Variable load conditions requiring enhanced protection

- TVV-Type Fluid Coupling: High-demand applications with critical performance requirements

Industry Implementation Guidelines

Selecting the appropriate Fluid Coupling requires careful consideration of operational requirements and performance expectations. The T-type Hydrodynamic Coupling serves adequately in standard applications, while the TV-type Fluid Coupling addresses more demanding operational conditions. For the most challenging applications where maximum equipment protection is paramount, the TVV-type Hydrodynamic Coupling delivers uncompromising performance.

Future Development Trends

The evolution of Fluid Coupling technology continues to focus on enhanced efficiency and smarter operational control. While the fundamental principles of Hydrodynamic Coupling operation remain constant, ongoing refinements in chamber design and fluid dynamics promise further improvements in performance and reliability.

About Fluid Coupling Technologies:

Fluid Coupling devices represent essential components in modern industrial power transmission systems, providing crucial protection and performance enhancement through Hydrodynamic Coupling principles. The progression from T-type to TV-type and TVV-type configurations demonstrates the continuous innovation in this critical field of industrial technology.